Intelligent Robotics for Critical Infrastructure

Autonomous robots capture structural data. AI delivers actionable insights. Your assets last longer.

Core Capabilities

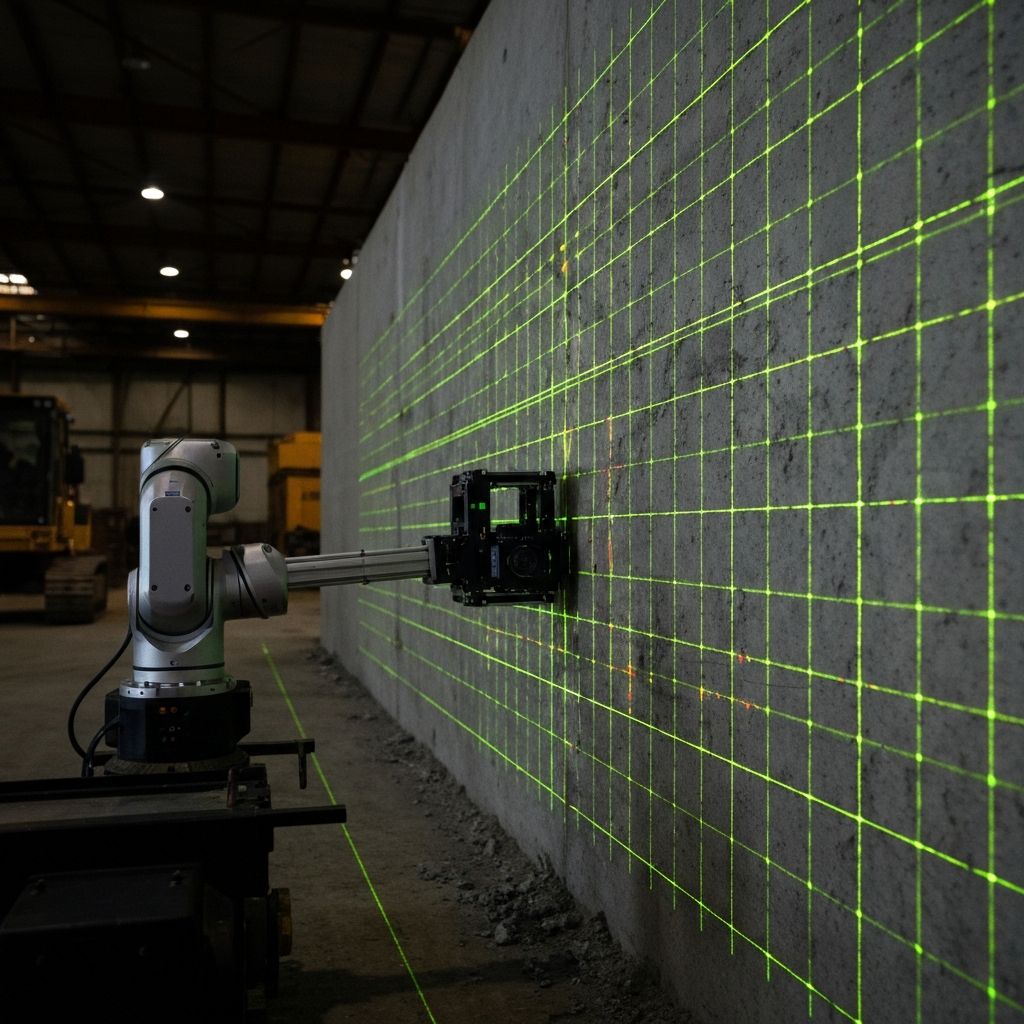

Robotic Inspection

Steel, concrete, and coating conditions. Sub-millimeter defect detection. Reduced human exposure.

AI Analysis

Corrosion mapping. Crack propagation tracking. Automated severity classification.

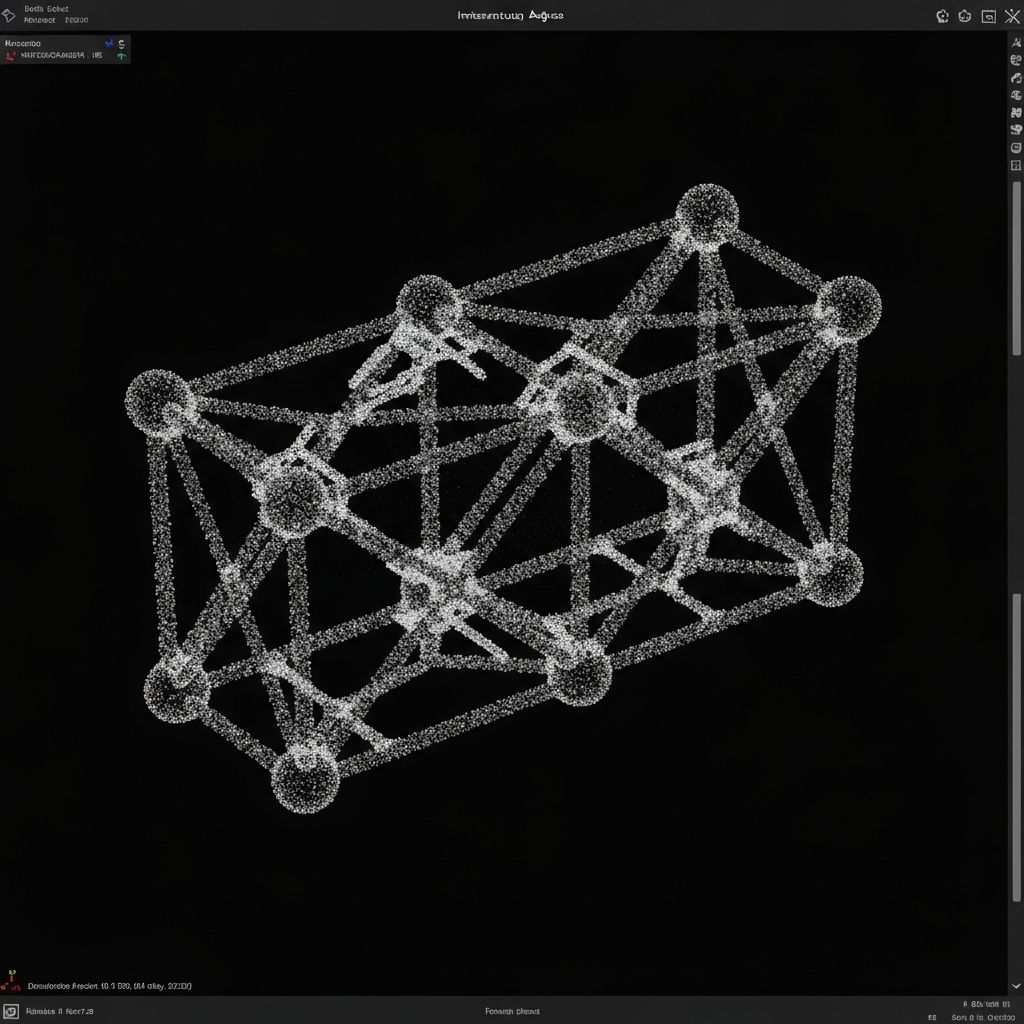

Digital Twin Modeling

High-fidelity 3D asset reconstruction. Engineering-grade measurements. Temporal comparison.

Risk Reduction

Predictive maintenance scheduling. 40% fewer unplanned shutdowns. Extended asset lifecycles.

Infrastructure ages. Data keeps it safe.

Bridges. Pipelines. Storage tanks. Power plants. The physical assets that power economies require continuous monitoring. Our robots go where humans cannot.

85%

Faster inspections

40%

Cost reduction

0

Human exposure

Research-Driven Innovation

As InnovBot, this technology received over $3M in NSF funding to advance robotic inspection research.

Government-backed R&D. Peer-reviewed methodologies. Proven in the field across energy, transportation, and manufacturing sectors.

Purpose-Built Systems

Crawler Systems

Magnetic and tracked robots for tanks, vessels, and pipelines. Ultrasonic thickness measurement. Real-time data transmission.

Vision Platform

Multi-spectral imaging. Automated defect detection and classification. Millimeter-accurate measurements.

Digital Twin Engine

Point cloud to CAD conversion. Structural analysis integration. Change detection over time.

Serving Critical Sectors